Solutions

Utilities

Utility-Scale CSP with TES Projects

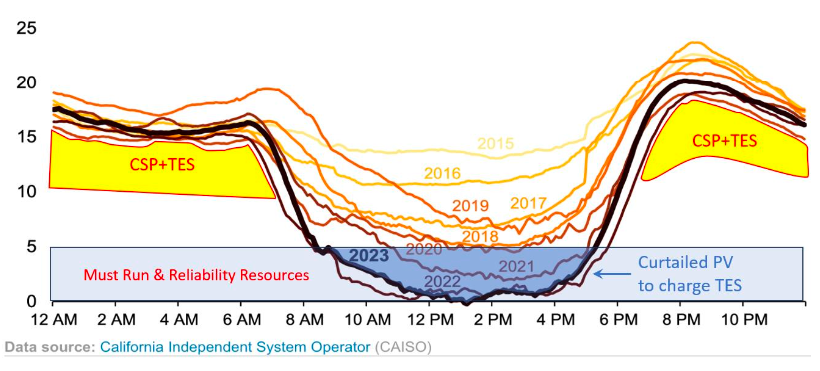

The market driver for CSP+TES can be seen in the graph below, often called the “duck curve”. It shows the electricity demand over one full day. The various dated lines, the net load, show what must be provided by the grid operator.

Over the years, as more solar capacity has come online in California, there is a growing drop in net load in the middle of the day when solar generation tends to be highest, and this presents a challenge for grid operators. Unlike conventional power plants, solar and wind resources can’t be fully dispatched at will to help meet demand, and utilities must curtail them with growing frequency to protect grid operations. As more solar capacity comes online, conventional power plants are used less often during the middle of the day, and the duck curve deepens.

The duck curve presents two challenges related to increasing solar energy adoption. Conventional power plants must be available and able to quickly ramp up electricity production to meet consumer demand. That rapid ramp up makes it more difficult for grid operators to match grid supply with grid demand in real time. The factors contributing to the curve reduce the amount of time a conventional power plant operates, which results in reduced energy revenues. If the reduced revenues make the plants uneconomical to maintain, the plants may retire without a dispatchable replacement, decreasing the reliability of the grid. However, the duck curve has created opportunities for energy storage. The large-scale deployment of energy storage systems, such as batteries or thermal energy storage, allow some solar energy generated or collected during the day to be stored and saved for later generation, after the sun sets.

CSP’s Key Attributes & Capabilities

- With its long duration thermal energy storage, CSP plants can be designed to operate at full load 24 hours a day if and when needed.

- CSP plants are flexible in the design and operational phases, allowing capability to meet most demand profiles.

- CSP plants can easily be hybridized – with PV, natural gas, biogas, green hydrogen, or green ammonia, allowing operation 365 days a year regardless of the weather.

- CSP plants can be “Made in America” minimizing supply chain challenges.

- CSP plants are synchronous generation with the ability to provide a range of grid reliability services, such as voltage and frequency regulation and short circuit capacity.

- CSP plants can work in high ambient temperatures, as proven in Abu Dhabi, Chile, Dubai, and Morocco.

- Can be used to supply 24/7 electricity to the grid or to manufacture green ammonia, the best long-distance carrier for green hydrogen.

- Costs continue to decrease, 47% reduction in the past decade and an additional 35% reduction is predicted by IRENA and supported by CSP’s early position on the learning curve.

Data Centers

Renewable Energy Solutions for Top Data Center Companies

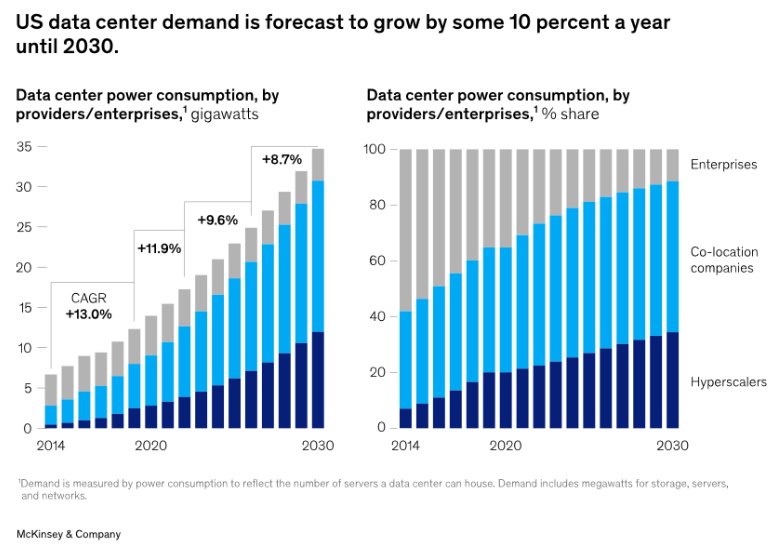

SolStor is prepared to facilitate a transformative era in renewable energy solutions tailored to meet the rigorous demands of the world’s leading data center companies. The growing uses of Artificial Intelligence (AI) are driving the need for new data centers and the associated energy needs. As we observe the rapid digitalization of the global economy, the role of data centers has become indispensable, and so has their energy consumption.

Our Target Market: TOP 10 Data Center Companies

Our target market comprises the top data center companies, which are recognized as the backbone of cloud services and data management worldwide. These industry giants are increasingly committed to sustainability and are under considerable pressure to reduce their carbon footprint, making them ideal strategic partners for our comprehensive clean energy solutions.

SolStor offers an unprecedented value proposition: the ability to supply data centers with reliable, 100% renewable electricity around the clock regardless of weather. Our innovative hybrid approach combines PV for the daytime and CSP + TES for nighttime, incorporating electrical heaters for curtailed energy and a green fuel burner to assure reliable energy day and night, cloudy or bright. This strategy not only aligns with the sustainable energy goals of these companies but also provides a hedge against the volatility of traditional energy markets.

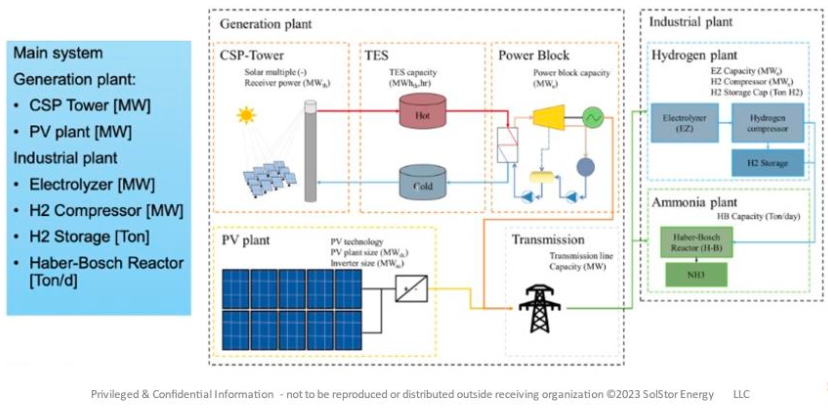

eFuels

Green Hydrogen, Green Ammonia, and Sustainable Aviation Fuel

Green ammonia produced using renewable energy sources does not emit carbon dioxide during production and therefore its use will be key to reducing emissions in the “hard to abate” sectors that currently use conventional ammonia produced from carbon-intensive natural gas. As the production of green ammonia requires a steady source of electricity and some thermal energy, CSP+TES is ideally suited to deliver both and therefore combining CSP+TES with PV+BESS has many advantages over PV and wind.

- Lower Cost per kg of H2, NH3, and SAF: The combination of CSP and PV allows for optimal utilization of solar energy, leading to lower production costs.

- Higher Output: CSP+PV systems can generate a higher output of green hydrogen and ammonia. In addition to providing electricity, CSP systems provide the high- temperature heat which drives the thermochemical reactions needed to produce ammonia. The PV system provides the electricity needed for the electrolysis process in hydrogen production. Together, they ensure a continuous and efficient production process.

- Continuous Operation: Because CSP+TES can operate continuously even when the sun isn’t shining, it provides a steady supply of heat for the production of green hydrogen, ammonia, and SAF, leading to higher output.

- Scalability: CSP+TES systems can be scaled up to achieve economies of scale, leading to lower cost per unit of energy.

- Less Land Use: CSP+TES systems can generate more energy in the form of heat per unit of land area compared to PV, making them a more suitable option for locations with limited available land.